Product

-

Steelworks Parts

Steelworks Parts

Cokes Plant

Cokes plant produces coke by hot-dried coal method in an integrated steelworks.

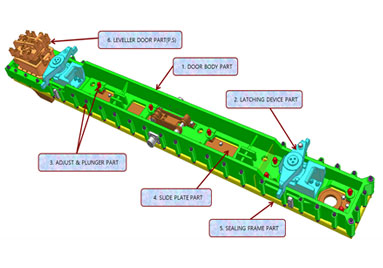

Coke Oven Door

The coke oven door is a core facility of the coke plant and is an environmental item that prevents harmful gases generated during the drying process from leaking to the outside. Our oven doors have a high performance sealing capacity of over 600mmAq without gas leakage even under high pressure inside the coke plant, and supply them to the world's leading steelworks. In addition, this product was registered as a world-class product in 2010 and has maintained its certification until now, and is recognized for its excellence in quality worldwide.

-

Coke Oven Door

- Material FC200~300, FCH, FCD400~600

- Size 5.5 ~ 7.8m

- Weight 2.0 ~ 6.5 ton

-

Door Frame

- Material FC200~300, FCH, FCD400~600

- Size 5.7 ~ 8.2m

- Weight 1.5 ~ 5.0 ton

-

Oven Door Body

- Material FC200~300, FCH, FCD400~600

- Size 5.5 ~ 7.8m

- Weight 1.5 ~ 4.0 ton

-

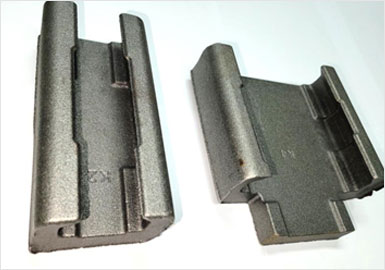

Leveller Door Ass'y

- Material FC250, FCD400, Steel, etc

- Size 0.8 ~ 1.2m

- Weight 0.2 ~ 0.5 ton

-

Sealing Plate, Frame

- Material SUS, High tensile steel

- Size 5.5 ~ 7.8m

- Weight 70 ~ 200kg

-

Gooseneck, Elbow Pipe

- Material FC200~300, FCH, FCD400~600

- Size 0.8 ~ 1.2m

- Weight 0.5 ~ 1.2 ton

-

Ascension Pipe Lids

- Material FC200~300, FCH, FCD400~600

- Size 0.8 ~ 1.5m

- Weight 0.5 ~ 1.2 ton

-

Waste Gas Boxes

- Material FC200~300, FCH, FCD400~600

- Size 0.8 ~ 1.8m

- Weight 0.8 ~ 2.0 ton

-

Wall Protection Plate

- Material FC200~300, FCH, FCD400~600

- Size 5.5 ~ 8.2m

- Weight 1.0 ~ 4.0 ton

Sinter/Pellet Plant

A plant that produces sintered ore by mixing secondary raw materials such as limestone with powdered iron ore in an integrated steel mill and heating it at high temperature.

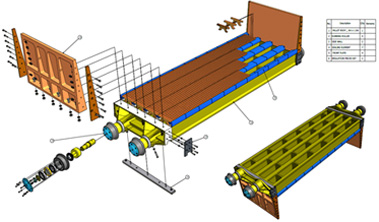

Sinter Pallet Car / Pelletizing Pallet Car

In the blast furnace operation of a steelworks, , if pulverized iron ore is directly charged into the blast furnace, the flow of reducing gas is not smooth inside the blast furnace, resulting in poor furnace conditions and reducing the amount of discharge. Therefore, when the blast furnace is operated, a sintered ore, which is used to ensure a smooth flow of reducing gas and facilitate charging of the blast furnace by lumping powdered iron ore to a size of about 5 to 50 mm. Such sintered ore is produced in a downward suction-type sintering plant, and a cart for charging powdered iron ore in the sintering plant is called a pallet car.

-

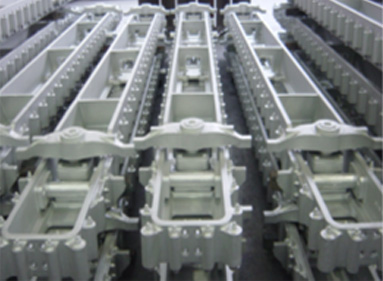

Pallet Car

- Material FCD400~600, Hi-Si FCD,

G17CrMo5-5 - Size 2.0 ~ 5.5m

- Weight 2.3 ~ 9.0 ton

-

Pallet Car Body

- Material FCD400~600, Hi-Si FCD,

G17CrMo5-5 - Size 2.0 ~ 5.5m

- Weight 1.6 ~ 6.0 ton

-

Pallet Car Side Wall

- Material FCD400~600, Hi-Si FCD,

GX40CrNiSi25-12, G20Mo5 - Size 1.0 ~ 1.5m

- Weight 0.3 ~ 0.7 ton

-

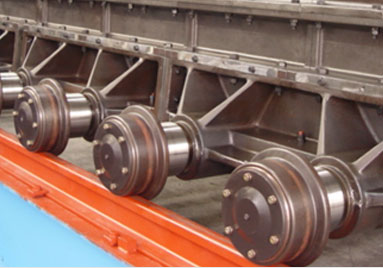

Running Roller Ass'y

- Material SCM440, S45C, etc.

- Size 0.5 ~ 1.0m

- Weight 0.2 ~ 0.5 ton

-

Grate Bar

- Material Steel Casting

- Size 0.2 ~ 0.4m

- Weight 3.0 ~ 6.0kg

-

Insulation Pieces

- Material FCD 400 ~ 600

- Size 0.2 ~ 0.4m

- Weight 7.0 ~ 13.0kg

-

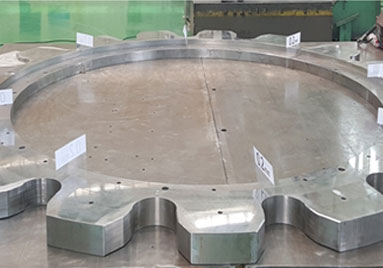

Gear Rim

- Material 42CrMo4

- Size 3.5 ~ 4.5m

- Weight 3.0 ~ 5.0 ton

-

Drive Station

- Material SCM440, S45C, etc.

- Size Ø 3.5m X 4.5m

- Weight44 ton

-

Tipping Station

- Material SCM440, S45C, etc.

- Size Ø 3.5m X 4.5m

- Weight21 ton

KOR

KOR